Shell and Tube Heat Exchanger Thermo-Fluid

There are two different construction types.

It’s possible to create a design using a little construction space using the customer’s data. The Thermo-Fluid S is connected directly between the oven pipe (or the heating system) and the chimney.

The operating temperatures are up to 300°C (standard). The Thermo-Fluid S is low maintance with low pressure drop in the flue gas. Depending on the application you can have energy savings up to 15 %.

The operating temperatures are up to 300°C (standard). The Thermo-Fluid S is low maintance with low pressure drop in the flue gas. Depending on the application you can have energy savings up to 15 %.

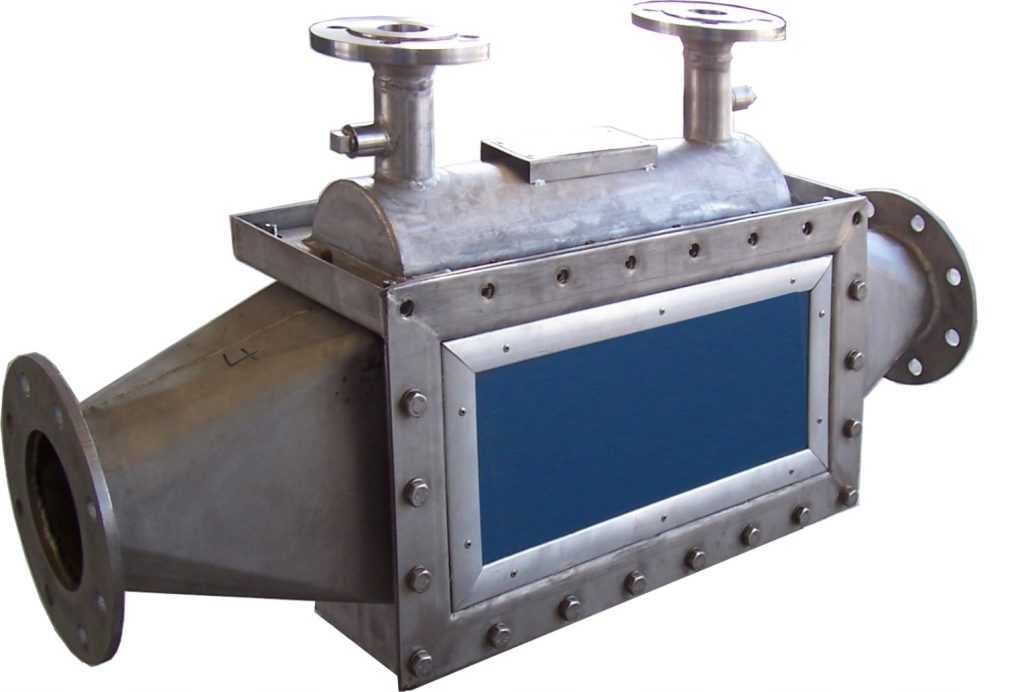

A bigger construction is the Thermo-Fluid M, which is optimised for utilisation of waste heat from process air, flue gas or exhaust air. An energy yield of up to 1600 kW is possible, whereupon the pressure drop in the process air is less than 1.5 mbar. The pressure drop in water circuit is less than 200 mbar.

This Shell and Tube heat exchanger is low maintance using the small type of construction. The Thermo-Fluid M modular and the standard temperatures are up to 300°C too.

This Shell and Tube heat exchanger is low maintance using the small type of construction. The Thermo-Fluid M modular and the standard temperatures are up to 300°C too.