Plate heat-exchanger

- operating temperatures up to 600°C (standard)

- completely made of stainless steel

- heat recovery factor up to 85%

- pressure-resistant up to 150 mbar

- completely welded

- high degree of efficiency

- without seelings

- up to 100% gas-tight

- low maintenance

- small construction volume

- flexible coordination due to single-item or small-lot production

- distance between plates from 3.5 mm to 7 mm

- available in the structural shapes K, L, U and LU

- complete seperation of the two gas flows

- different current lines possible

- different volume flows for exhaust and feed air, applicable for the temperature control of useful heat

Structural shape

In principle, the shape is arbitrary. The choice takes place after consulting with the customer and with similar power are no costs involved. It depends on the technical demands of the application. The structural shape X (crossflow) isn't possible with the ´ THERMO GAS System.

The choice of the structural shape depends on the customer demands. Nevertheless, not every structural shape is qualified as well for each function.

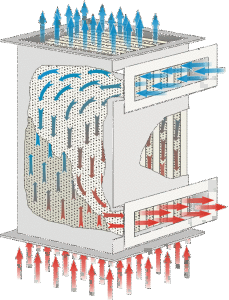

Shape K

An absolute classic which is employed very often if pollution in the gas flows is suspected. A opening for maintance can be build on the complete straight line. The pressure drop at the straight line is relative low (depends on design). An integrated bypass at both lines is possible either with or without valve. Different volume flows can be realised.

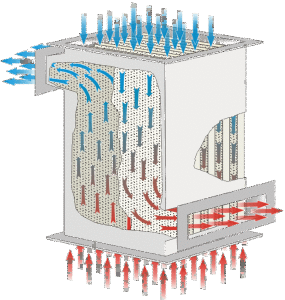

Shape L

This plate heat exchanger is qualified for high volume flows and a thermal efficiency¹ up to 85 % caused of it’s internal condition.

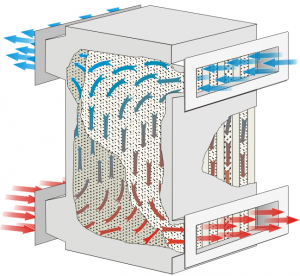

Shape U

This structural shape is especially qualified for small plate heat exchangers. This structural shape is although qualified for plate heat exchangers which should streamed vertically.

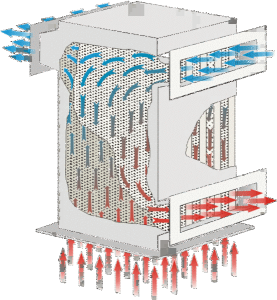

Shape LU

This structural shape is an effective combination of the structural shapes L and U. It’s used for constructions which are streamed vertically. High thermal effiency¹ up to 85 % are possible and high volume flows on the L-side should employed expedient.

¹ A thermal effiency from e.g. 75% supply air means:

The supply air raise up by a temperature, which equates 75 % of the temperature difference between the hot (exhaust air) and the cold input (supply air).

Example:

Exhaust air input = 110°C • Supply air input = 10 °C

Temperature difference represent accordingly 100°C

Thereof 75% = 75°C

Out of it results a supply air output temperature

from 10°C + 75°C = 85°C